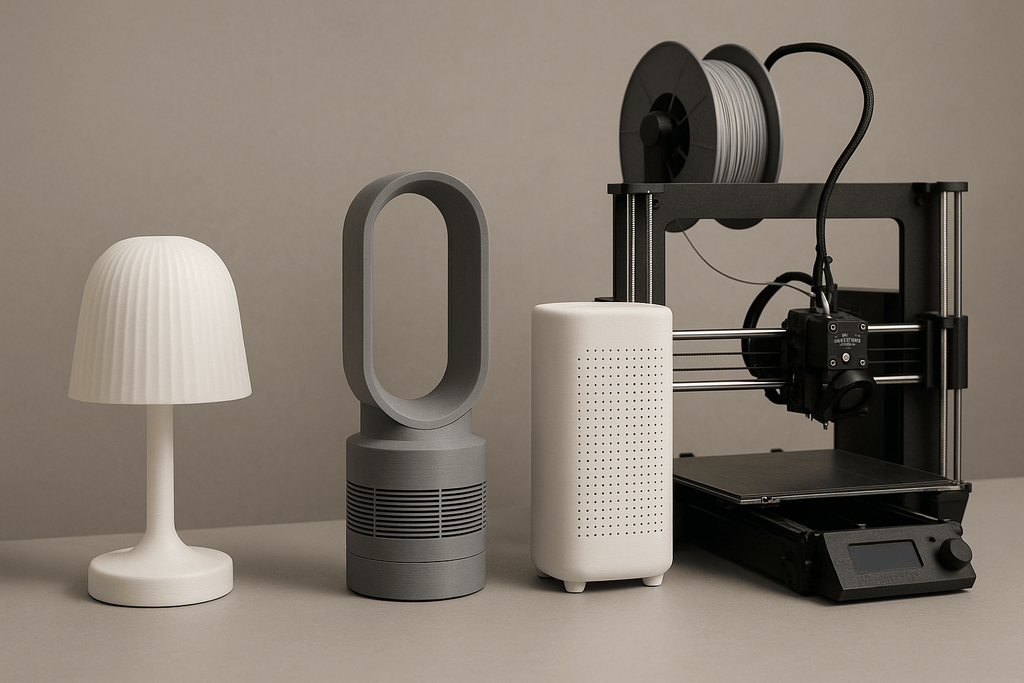

Behind the Build: Our Custom 3D-Printed Lamp, Fan & Air Purifier

Introduction

In today’s market, speed, customization, and quality reign supreme. Our custom‑made 3D‑printed line—encompassing a lamp, fan, and air purifier—reflects this ethos. Drawing from the rich heritage of craftsmanship and merging it with modern additive manufacturing, we’ve created a product suite that is both traditional in its attention to detail and forward‑thinking in its delivery model. This article takes you through our process—from ideation to production—highlighting design choices, material selection, printing strategy, assembly, safety controls, and sustainability considerations.

1. Design & Concept Development

From initial sketches to 3D CAD models, our design workflow builds a bridge between classic product development and iterative digital refinement. Traditional designers conduct concept interviews and physical sketches, but once integrated into CAD, we enter agile cycles—rapidly prototyping and testing revisions to geometry, form, and functionality.

We drew inspiration from industry leaders such as Gantri, the lighting company that leverages 3D printing to produce distinctive lamps without traditional tooling. They iterate designs in weeks, not months, while offering thousands of customizable variants; that kind of flexibility is now within reach WIRED+1WIRED+1.

For our lamp, the design prioritizes both aesthetic appeal and thermal management. The fan’s geometry maximizes airflow and structural integrity, and the air purifier’s enclosure is laid out to optimize seals and filter placement. Each component began with hand‑drawn sketches, refined in CAD, and rapidly prototyped to assess ergonomics, assembly fit, and structural robustness.

2. Material Selection & Printing Technology

We opted for Fused Deposition Modeling (FDM/FFF)—now the most widely used process in desktop and industrial settings—for components that require mechanical strength and low cost Wikipedia. FDM aligns with our goal of on‑demand customization and allows materials to be swapped easily between PLA, PETG, and ABS.

-

Lamp: Printed in PLA or PLA‑blend copolymers. PLA emits minimal VOCs and offers fine detail, making it ideal for aesthetic finishes and safe indoor use.

-

Fan housing: PETG or ABS for higher heat resistance and structural strength.

-

Purifier body: PETG with reinforced filaments for more durability and tight sealing around filter modules.

Utilizing additive manufacturing allows part consolidation—what once required five pieces in injection molding can now be printed as one monolithic design—simplifying assembly while cutting part count and potential failure points Wikipedia.

Research also shows that additive manufacturing enables mass customization and decentralized production—aligning with our goal of rapid, localized manufacture with minimal waste Wikipedia+1thereyouhaveit3d.com+1.

3. 3D Printing: Hardware, Layer Settings & Post‑Processing

Our production printers are mid‑range desktop FDM machines capable of 0.1–0.2 mm layer heights, with tight tolerances (± 0.2 mm) to ensure proper fit between printed parts and purchased components.

-

Lamps are printed at 0.12 mm for surface quality and smoother visual appeal, followed by sanding and painting. We use water‑based paints selected for matte finish and low emissions, echoing practices used by Gantri’s hand‑finishing stages WIRED+1WIRED+1.

-

Fan and purifier parts are printed at 0.2 mm for faster throughput. Post‑processing includes deburring, light sanding, and tight fitting of snap‑fit joints.

If we employed resin or powder‑bed methods for advanced components in the future, we would follow decaking/powder removal stages. However, for now, our FDM focus avoids those steps and keeps costs predictable.

4. Assembly & Functional Integration

Lamp

Printed components are fitted with pre‑wired LED modules, power switch, AC connector, and heat‑sink assembly. We ensure internal thermal clearance and adequate ventilation. Wiring is routed through internal channels, and parts interlock precisely to enclose electrical components safely.

Fan

The fan houses a brushless motor seated inside a printed housing with integrated airflow‑optimizing vanes. Fastening is handled with printed mounting bosses, reducing reliance on metal inserts. Air inlets and outlets are designed for laminar flow to minimize turbulence and blade noise.

Air Purifier

This product borrows concepts from open‑source purifiers—like the Corsi‑Rosenthal design, though miniaturized—using standardized HEPA and activated carbon filters housed in a printed enclosure. The fan module draws air through the filter stack; seals are achieved via printed dovetail joints and silicone gaskets for bypass prevention Wikipedia.

Iteration cycles allowed us to fine‑tune the geometry so that filters seat snugly and airflow is optimized. We also incorporated guides for future user replacement.

5. Quality Control, Safety & Air‑Filtration Standards

VOC & Particle Emission

Consumer‑level FDM printing can release ultrafine particles (UFPs) and volatile organic compounds (VOCs), especially when using ABS or nylon. However, studies have shown that for PLA, emissions remain well below safety thresholds—especially when prints are infrequent (2–3 prints per day) and spaces are ventilated naturally reddit.com+23dprinting.stackexchange.com+24dfiltration.com+2. For extra assurance, we monitor emissions and advise customers on proper room ventilation.

Filter Performance

We test airflow, pressure drop, and CADR (clean air delivery rate) to verify filter performance. Inspired by biomimetic particle filters—such as tortuous channel designs that outperform standard HEPA in pressure drop while maintaining capture efficiency—we explore those structures for future versions arxiv.org.

Regulatory & Safety Protocols

Each unit undergoes a final inspection checklist: electrical safety (ground continuity, insulation), mechanical integrity (fasteners, fitment), and filtration test (leak checks, bypass evaluation). We benchmark against common industry standards for small appliance safety and indoor air quality.

Conclusion

Our custom‑made 3D‑printed line—the lamp, fan, and air purifier—exemplifies how additive manufacturing can blend tradition with innovation. We start with respect for design iteration and craftsmanship, yet deliver with the agility of modern on‑demand production.

Customers get personalized products with quick turnaround and reduced waste. By producing parts locally via 3D printing, we avoid tooling costs and long shipping chains—supporting both sustainability and speed-to-market.

Looking ahead, as materials and printer technologies evolve, we’ll advance to dual-color parts, fiber-reinforced composites, and even more complex filtration geometry. The future for this product line is one of continuous improvement—rolling out version‑two, then version‑three—much like the cadence of software updates in the digital world.

References & Further Reading

-

The rise of decentralized manufacturing and mass customization enabled by 3D printing mdpi.comWikipedia

-

Advantages of additive manufacturing for reduced waste, localized production, and lightweight designs Wikipediasharrettsplating.comamfg.ai

-

Gantri’s successful 3D-printed lamp model and design-to-production process WIRED+1WIRED+1

-

Health & emissions considerations for FDM 3D printing, especially for PLA versus ABS/nylon 3dprinting.stackexchange.comreddit.com4dfiltration.com

-

Open-source air purifier design and airflow-filter modeling strategies airsupportproject.comWikipediaarxiv.org