Unlock Efficiency with Custom 3D Printing | Save Time & Money

Unlocking Efficiency: How Custom 3D Printed Parts Save You Time and Money

Introduction

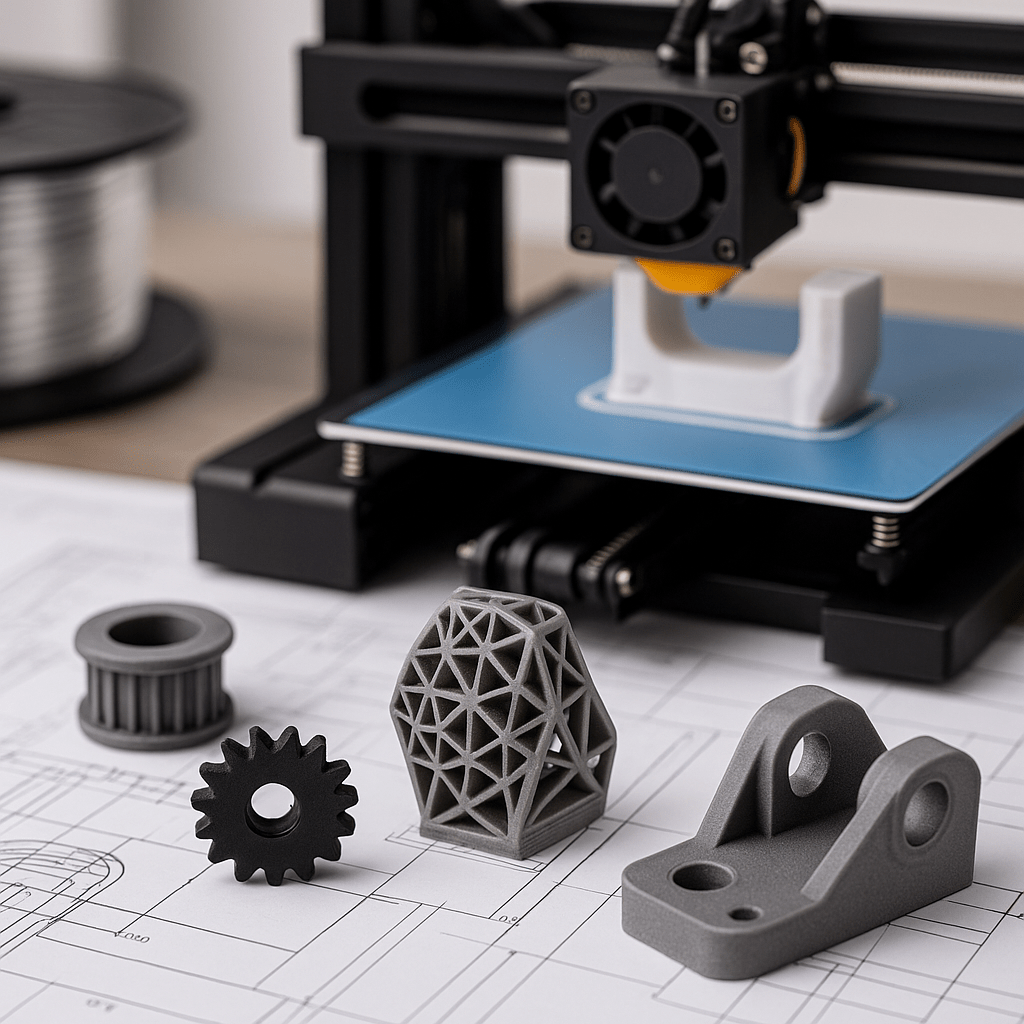

In today's manufacturing world, efficiency is more than a competitive advantage—it's a necessity. Businesses and innovators alike are seeking smarter ways to produce components that are both cost-effective and timely. Custom 3D printing has emerged as a game-changing solution, offering the ability to produce strong, lightweight, and highly functional parts with minimal waste.

Rather than relying on slow, expensive, and inventory-heavy traditional methods, companies are leveraging custom 3D printing to rapidly prototype, reduce material costs, and bring products to market faster. Whether you're a startup designing your first product or an enterprise optimizing your supply chain, the benefits of custom 3D printed parts are undeniable.

Stop compromising! Learn how investing in custom 3D printing with HydroFlo can optimize your budget and timeline.

1. Waste Less, Save More

Traditional manufacturing processes like CNC machining and injection molding are inherently wasteful. Material is often cut away or discarded during the production process. According to the U.S. Department of Energy, additive manufacturing can reduce material waste by up to 90% compared to subtractive manufacturing methods (NEXA3D).

3D printing builds objects layer-by-layer using only the material needed for the part, drastically reducing excess. This not only saves on material costs but also lessens environmental impact. Companies using recycled filament or biodegradable materials such as PLA can take sustainability a step further—great for your brand image and even better for the planet.

Example: A small repair shop eliminates bulk orders for spare machine parts and instead prints what they need, when they need it, using recycled plastic. No more wasted materials. No more expired inventory.

2. Speed Up Prototyping Cycles

Prototyping with traditional manufacturing can be slow and expensive. Creating molds or tooling for a new design might take weeks and cost thousands. In contrast, 3D printing allows for rapid prototyping—you can go from CAD model to physical part in as little as 24 hours.

According to Protolabs, companies that utilize 3D printing for early-stage prototyping often cut product development timelines in half. This speed empowers designers to iterate quickly, test multiple design concepts, and refine functionality without blowing the budget.

Example: A consumer electronics startup prints five variations of a housing design overnight. They test and evaluate the next day. One week later, they’re ready for production.

3. Manufacture On Demand, Eliminate Inventory

Inventory costs are a silent killer for many businesses. Stocking parts "just in case" ties up capital, requires warehouse space, and leads to obsolete items. Custom 3D printing turns this model upside down. Parts can be produced on demand, only when needed.

This shift toward leaner operations helps companies adapt to market fluctuations and avoid the risks of overproduction. According to Forbes, companies that adopt digital manufacturing see major gains in flexibility and responsiveness.

Example: A technician in the field needs a custom valve housing. Instead of waiting 3–5 days for shipping, they print it on-site using a HydroFlo 3D printer in less than 8 hours.

4. Stronger, Lighter, Better

3D printing enables designers to create parts with complex internal geometries that are impossible to produce with traditional methods. This means parts can be both stronger and lighter—ideal for aerospace, automotive, and robotics industries.

By using lattice structures or hollowed-out cores, manufacturers can drastically reduce weight while maintaining strength and durability. Companies like GE have used this approach to replace hundreds of components with fewer, more efficient parts. Their 3D-printed fuel nozzle, for example, reduced part count from 20 to 1 and decreased weight by 25% (GE Aviation).

Example: A drone company prints propeller arms with hollow lattice structures, cutting weight by 40% and extending battery life without compromising strength.

5. Bottom-Line Business Benefits

At the end of the day, time is money. 3D printing shortens development timelines, reduces labor, and minimizes waste—all of which translate to direct savings. By eliminating costly molds, enabling faster design changes, and slashing shipping delays, companies are reporting 20% to 60% reductions in production costs for low-to-mid volume manufacturing (i4verse).

You also gain a competitive edge. When your competitors are stuck waiting on delayed parts or tooling revisions, your team is already testing the next version.

Example: A boutique appliance brand avoids a $100,000 tooling investment by 3D printing small-batch components, allowing for flexibility and faster response to customer feedback.

Conclusion

Custom 3D printing is more than a trend—it's a proven strategy for companies serious about reducing waste, saving money, and staying agile. From prototyping to full-scale production, the benefits are real and the savings are measurable.

Whether you're looking to simplify operations, launch a new product, or eliminate unnecessary overhead, custom 3D printing through HydroFlo gives you the tools to move smarter and faster.

Stop compromising! Learn how investing in custom 3D printing with HydroFlo can optimize your budget and timeline.